PERSPECTIVE

WORLD-GENERATION NOV/DEC 2015

12

There’s a new product destined to make

an impact at coal-fired utilities across North

America in the coming years. It’s the pipe

conveyor—so named for how the conveying

belt is rolled into a tube—and it can be right-

fully considered the conveyor of the future for

applications that require spill- and dust-free

conveyance of coal and coal by-products,

especially ash.

In fact, the pipe conveyor isn’t new at all.

It was developed in Japan in the late 1970s,

but its design was quickly patented world-

wide, and though a handful of license part-

ners marketed the technology outside of

Japan in the following

years, those patents sti-

fled innovation until their

expiration in the late

1980s and early 1990s.

But even then pipe

conveyors were seen as

having high capital costs

and therefore consid-

ered not cost-competitive

with trough conveyors, so most installations

were still to be found in Japan, where environ-

mental regulations were relatively strict.

In the last twenty years, however, design

improvements have reduced the cost of con-

structing pipe conveyors—and improved their

operation—while environmental regulations

on the handling of coal and coal by-products

have tightened in many developed and devel-

oping countries.

Today there are dozens of pipe conveyor

installations in India alone, where both envi-

ronmental regulations and the need to pre-

vent spillage and other loss of materials have

made them a preferred product, used to move

everything from coal to alumina to copper

concentrate.

Still, one would be hard pressed to find

a pipe conveyor at a utility in North

America, and many utilities are shutting

down or reducing capital investments in

coal-fired plants. Minnesota Power, for

example, generates 75% of its power from

coal but will reduce the share of coal to just

one-third over the next 15 years.

But coal won’t be going away anytime

soon—it still makes up nearly 40% of electrici-

ty generation in the U.S.—and it is widely

believed the EPA will continue stiffening reg-

ulations on the use of coal and its by-products,

especially ash, which will necessitate new

technologies in bulk material handling.

Conventional trough conveyors will still have

a place at utilities, but they simply cannot pro-

vide the kind of dust-free containment that

will be mandated.

Pipe conveyors, on the other hand, can.

They resemble conven-

tional trough conveyors

at the loading and dis-

charge ends, but

between the two, idler

rollers transition the

belt into a tube, effec-

tively eliminating mate-

rial loss.

Plus, due to their

enclosed design, they don’t require covers,

and they can be fitted with triangular galler-

ies, both of which reduce the amount of steel

required in their construction. In addition,

they can be fitted with maintenance trolleys

instead of walkways, further reducing costs,

even down to lighting.

Also, pipe conveyors can go places con-

ventional conveyors can’t. They can handle

90-degree horizontal turns as well as 20%

steeper inclines. This has the added benefit of

reducing transfer points and the costs associ-

ated with them. It also makes them effectively

the only kind of conveyor capable of negotiat-

ing some topographically challenging areas,

especially large ones. Pipe conveyors can be

built in excess of 10 kilometers in length and

operate at 5,000 tons per hour.

Yet only a handful of companies have

experience designing pipe conveyors. Wolf

Point Engineers & Contractors—a full-service

engineering, procurement, and construction

services provider for the power, mining, and

industrial processing industries, and a divi-

sion of North Alabama Fabricating Company

(NAFCO)—recently entered into a strategic

alliance with CKIT, a world-renowned design-

er of pipe conveyor systems, to offer this tech-

nology to North American customers.

CKIT is a Cape Town, South Africa-based

materials-handling consulting and engineer-

ing company that has dozens of pipe conveyor

installations in Africa, Europe, and Asia,

including more than 50 in India. CKIT’s pipe

conveyors move everything from coal and

cement to paper pulp and ash.

Indeed, because of their closed design,

pipe conveyors promise to make their mark

well beyond power generating. They are great

for mines, given the frequent need to take

tight curves and steep inclines, and they are

ideal in any application that requires keeping

bulk materials dry—such as grain processing,

fertilizer processing, and steel production, to

name a few.

So while their use might be more or less

mandated in some areas eventually, pipe con-

veyors are just as likely to be adopted out of

practical necessity where raw materials or the

environment, or both, need an extra layer of

protection.

CKIT’s Pipe Conveyor Information Database

can be accessed at

/

secure/conveyor/pipe/indexpipe.htm

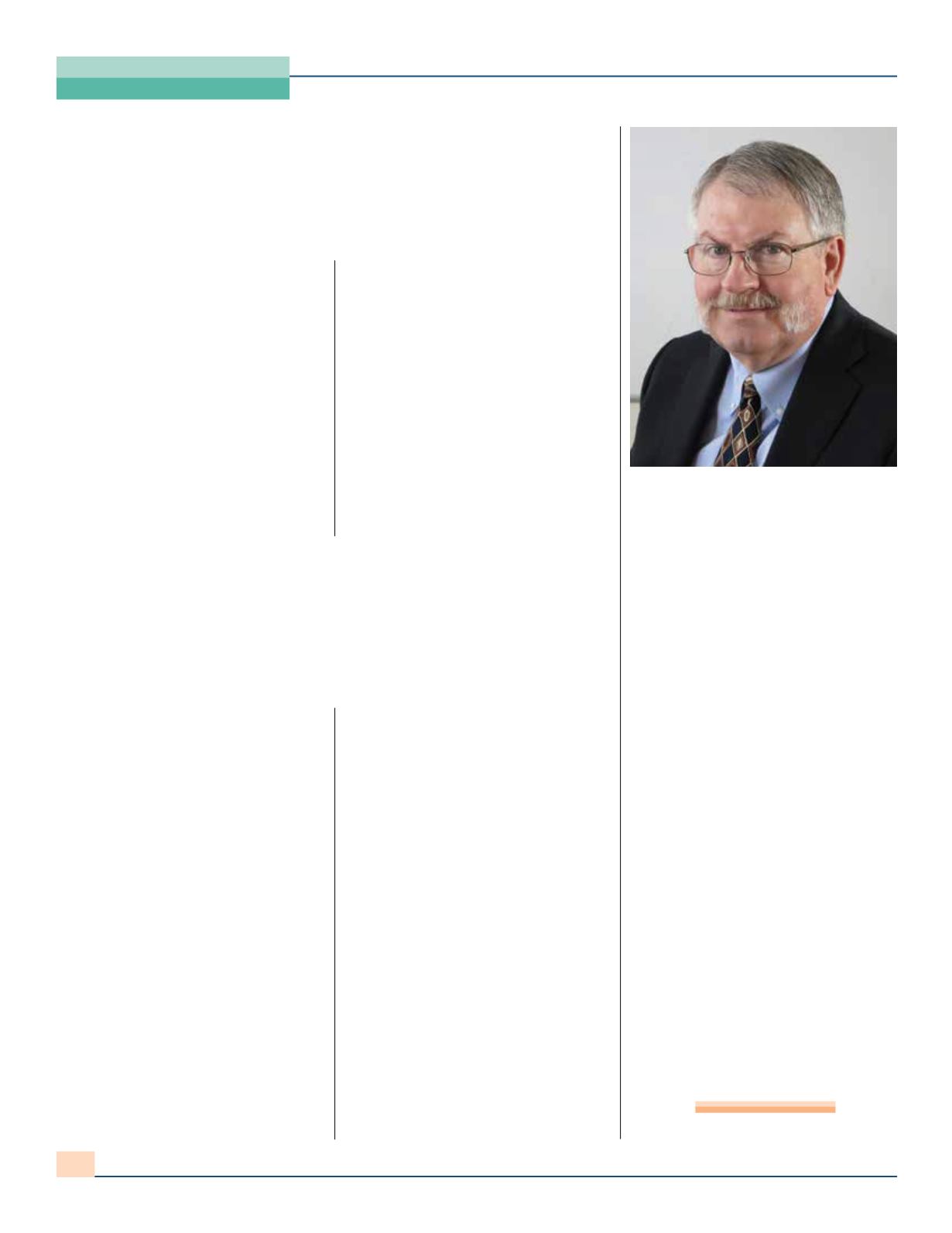

GOING DUST-FREE

BY BOB WILLIAMS,VICE PRESIDENT

WOLF POINT ENGINEERS & CONTRACTORS

Pipe conveyors can go places

conventional conveyors can’t.

They can handle 90-degree

horizontal turns as well as

20% steeper inclines. This has

the added benefit of reducing

transfer points and the costs

associated with them.